NEW STANDARDS FOR OMF SURGERY

Immediate bonding with the bone, less invasive implant fixation, and reduced surgical time.

BoneWelding® technology sets a new and superior standard for orthopedic implants: superior primary stability due to immediate bonding with the bone, less invasive implant fixation, and reduced surgical time. The BoneWelding® process employs gentle ultrasonic energy to induce controlled melting of pre-defined, polymeric implant components.

The pins are fused both into bone and to the plate using ultrasonic energy. Only monocortical fixation is needed, so tooth roots and blood vessels can be protected. Implantation of the pins takes only a few seconds and the polymer will set immediately. The plates are used in non-load-bearing fracture stabilization.

The pins are fused both into bone and to the plate using ultrasonic energy. Only monocortical fixation is needed, so tooth roots and blood vessels can be protected. Implantation of the pins takes only a few seconds and the polymer will set immediately. The plates are used in non-load-bearing fracture stabilization.

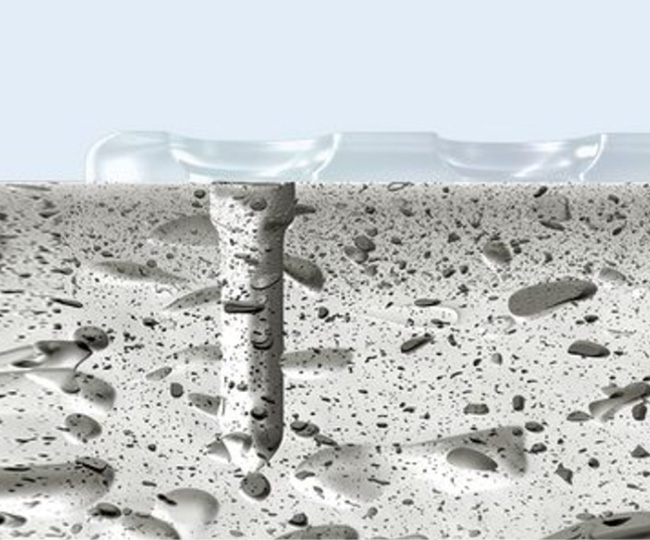

PREDRILLING

This picture illustrates the pilot hole, created using a specified BoneWelding® drill bit. This is easily done by drilling through a preformed hole in the resorbable plate.

IMPLANTATION WITH ULTRASOUND

Gentle pressure on the handpiece, together with ultrasonic vibration through the sonotrode, push the thermoplastic implant into the pre-drilled hole in the bone. This sets up shearing forces at the contact surfaces between the bone and polymer, causing small amounts of polymer to liquefy.

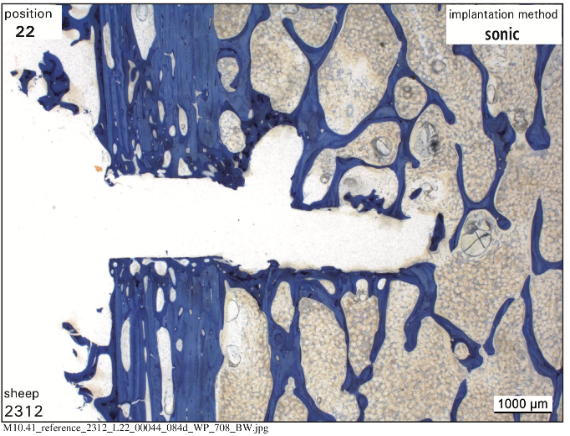

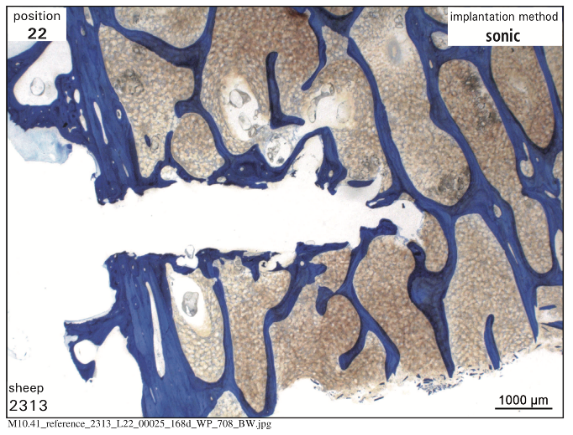

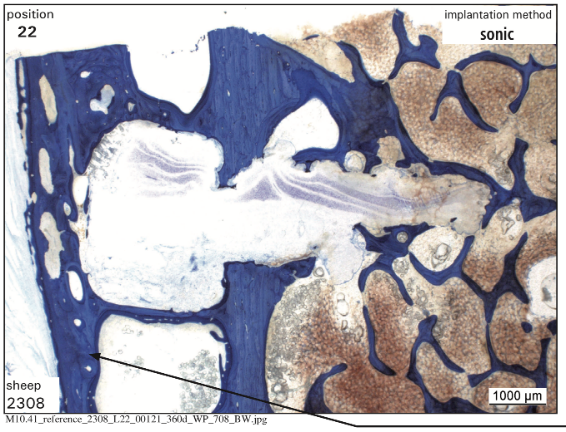

DEGRADATION OF

BONEWELDING® PIN

Only minimal inflammatory reaction during the degradation process without fibrous tissue formation at the bone-polymer interface.

The implants are completely absorbed within 12-24 months and eventually degrade into water and C02. Histopathological studies prove that the short ultrasonic pulse and the local melting of the polymer have no thermal side effects to the surrounding tissues.

The implants are completely absorbed within 12-24 months and eventually degrade into water and C02. Histopathological studies prove that the short ultrasonic pulse and the local melting of the polymer have no thermal side effects to the surrounding tissues.

RESORB PIN AND PLATE SYSTEM

The VetWelding Resorb pins and plates are made of 100% biocompatible and fully bioresorbable Poly-D,L-lactic Acid (PDLLA). The in vivo degradation of the pins and plates is based on the natural physiological process of hydrolysis, which results in a complete metabolization of the polymer into H2O and CO2.